AT-FH

Product features: Gleason parameter gear processing equipment is used to process the spiral bevel gears with grinding grade to ensure low backlash and low noise. The minimum backlash can be less than 2 arc minutes. Multiple precision-machined surfaces are easy to assemble and suitable for any installation direction. The design of the input and output shafts can be applied to the needs of various industrial applications. The high-precision ground spiral bevel gear set combined with the optimized planetary gear set can achieve a reduction ratio of 500:1.

Product introduction: The connection between the input end and the motor uses a collet-type locking mechanism, and is dynamically balanced to ensure the concentricity and balance of the interface at high input speeds, and zero backlash power transmission. The one-piece gearbox body ensures maximum rigidity and touch resistance. The complex structure and rigid design ensure that the highest torque and larger reduction ratio can be achieved under the condition of small size and light weight. Maintenance-free, no need to change lubricating oil, and long operating life.

Parameter Table

| Model No. | Stage | A Ratio^ | AT065FL AT065FL1 AT065FH AT065FC AT065FR1 | AT075FL AT075FL1 AT075FH AT075FC AT075FR1 | ATO90FL ATO90FL1 ATO90FH AT090FC ATO90FR1 | AT110FL AT110FL1 AT110FH AT110FC AT110FR1 | AT140FL AT140FL1 AT140FH AT140FC AT140FR1 | AT170FL AT170FL1 AT170FH AT170FC AT170FR1 | AT210FL AT210FL1 AT210FH AT210FC AT210FR1 | AT240FL AT240FL1 AT240FH AT240FC AT240FR1 | AT280FL AT280FL1 AT280FH AT280FC AT280FR1 | |

| Nominal Output Torque T2N | Nm | 1 | 1 | 25 | 45 | 78 | 150 | 360 | 585 | 1300 | 2150 | 3200 |

| 1.5 | 25 | 45 | 78 | 150 | 360 | 585 | 1300 | 2150 | 3200 | |||

| 2 | 24 | 42 | 68 | 150 | 330 | 544 | 1220 | 2010 | 3050 | |||

| 3 | 18 | 33 | 54 | 120 | 270 | 450 | 1020 | 1650 | 2850 | |||

| 4 | 13 | 28 | 48 | 100 | 224 | 376 | 860 | 1410 | 2300 | |||

| 5 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 2 | 7 | 12 | 12 | 33 | 91 | 91 | 91 | 195 | 358 | 358 | ||

| 10 | 24 | 28 | 68 | 150 | 208 | 208 | 430 | 846 | 846 | |||

| 15 | 18 | 33 | 54 | 120 | 270 | 312 | 645 | 1269 | 1269 | |||

| 20 | 13 | 28 | 48 | 100 | 224 | 376 | 860 | 1410 | 1692 | |||

| 25 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 35 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 1465 | |||

| 50 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 1465 | |||

| 3 | 75 | – | – | – | 120 | 210 | 312 | 585 | 1269 | 1269 | ||

| 100 | – | – | – | 100 | 224 | 376 | 780 | 1410 | 1692 | |||

| 125 | – | – | – | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 150 | – | – | – | 120 | 135 | 312 | 390 | 975 | 975 | |||

| 200 | – | – | – | 100 | 180 | 376 | 520 | 1300 | 1300 | |||

| 250 | – | – | – | 85 | 196 | 320 | 650 | 1210 | 1625 | |||

| 350 | – | – | – | 85 | 196 | 320 | 740 | 1210 | 1790 | |||

| 500 | – | – | – | 85 | 196 | 320 | 740 | 1210 | 1465 | |||

| Max.Acceleration Torque T2B | Nm | 1.2.3 | 1~500 | times of Nominal Output Torque | ||||||||

| Max. Acceleration Input Speed n1B | rpm | 1 | 1~5 | 7500 | 6500 | 5500 | 4500 | 3500 | 3000 | 2200 | 2000 | 1700 |

| 2 | 7~50 | 8000 | 8000 | 6000 | 6000 | 6000 | 6000 | 4800 | 3600 | 3600 | ||

| 3 | 75~500 | – | – | – | 8000 | 8000 | 6000 | 6000 | 6000 | 6000 | ||

| Standard Backlash | arcmin | 1 | 1~5 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| 2 | 7~50 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| 3 | 75~500 | – | – | – | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| Max. Radial Load F2rB Output d2 | N | 1.2.3 | 1~500 | 900 | 1100 | 1700 | 2700 | 4800 | 6600 | 11500 | 16000 | 18000 |

| Max. Axial Load F2aB Output d2 | N | 1.2.3 | 1~500 | 450 | 550 | 850 | 1350 | 2400 | 3300 | 5750 | 8500 | 9000 |

| Service Life | hr | 1.2.3 | 1~500 | 20000 | ||||||||

| Efficiency η | % | 1 | 1~5 | ≥98% | ||||||||

| 2.3 | 7~500 | ≥94% | ||||||||||

| Operating Temp | ℃ | 1.2.3 | 1~500 | (-)10℃~90℃ | ||||||||

| Lubrication | 1~500 | Syntheticlubrication oils | ||||||||||

| Noise Level(n,= 1500rpm, No Load) | dB (A) | 1.2.3 | ≤71 | ≤72 | ≤76 | ≤77 | ≤78 | ≤79 | ≤81 | ≤83 | ≤84 | |

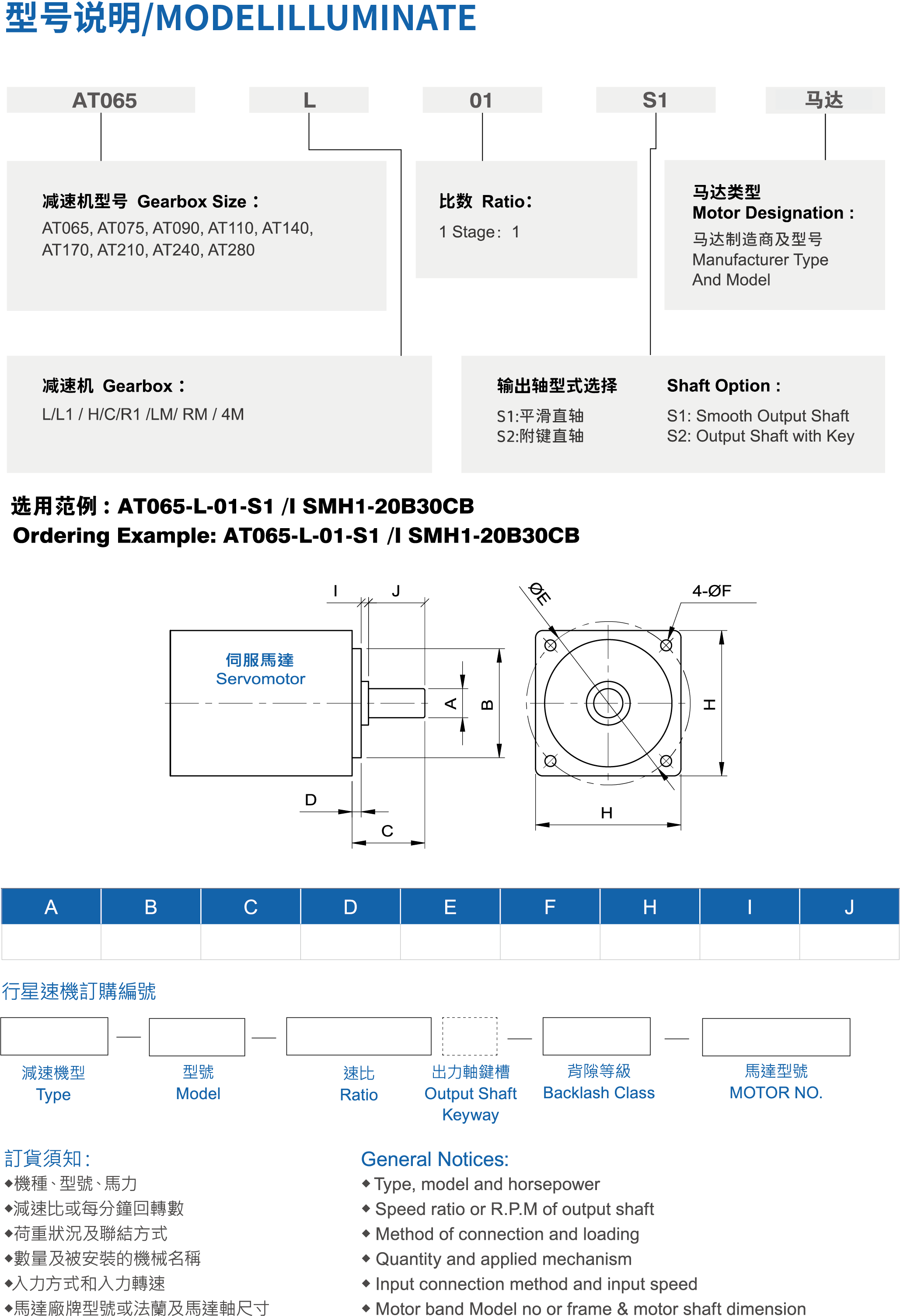

Ordering Instructions / Customer Fill Out