PGH115T T Series

Product features: high precision, high torque, high rigidity, high efficiency, high stability, low noise, low backlash.

Product introduction: It can be used with stepper motors or servo motors to reduce speed, increase torque, increase motor rotor inertia, improve rigidity, shorten start and stop positioning time, miniaturize motor power, and improve inertial load stability and reduce vibration. Single-stage can reach within 3 arc minutes, and double-stage can reach within 5 arc minutes.

Parameter Table

| PGH115 | Double-stage T-type | ||||||||||||

| Reduction ratio | i | 12 | 15 | 20 | 25 | 30 | 35 | 40 | 50 | 70 | 90 | 100 | |

| Rated output torque | Nm | 290 | 290 | 300 | 290 | 290 | 290 | 300 | 290 | 270 | 220 | 220 | |

| Maximum output torque | Nm | 3 times rated output torque | |||||||||||

| Rated input speed | rpm | 4000 | |||||||||||

| Maximum input speed | rpm | 8000 | |||||||||||

| Ultra-precision backlash | arcmin | ≤3 | |||||||||||

| Precision backlash | arcmin | ≤5 | |||||||||||

| Standard backlash | arcmin | ≤7 | |||||||||||

| Maximum radial load | N | 3420 | |||||||||||

| Maximum axial load | N | 2650 | |||||||||||

| Average service life | hr | 20000* | |||||||||||

| Full load efficiency | % | ≥94% | |||||||||||

| 0perating temperature | °C | .-10°C~+90°C | |||||||||||

| Lubrication | Synthetic lubricating grease | ||||||||||||

| Protection level | IP65 | ||||||||||||

| Installation method | Any | ||||||||||||

| Noise value(n1=3000rpm) | dB | ≤63 | |||||||||||

| Moment of inertia(T-Type) | kg.cm² | 0.65 | 0.65 | 0.65 | 0.65 | 0.60 | 0.60 | 0.60 | 0.58 | 0.58 | 0.58 | 0.58 | |

| Moment of inertia(Direct connection) | kg.cm² | 1.50 | 1.50 | 1.50 | 1.50 | 1.45 | 1.45 | 1.45 | 1.41 | 1.41 | 1.41 | 1.41 | |

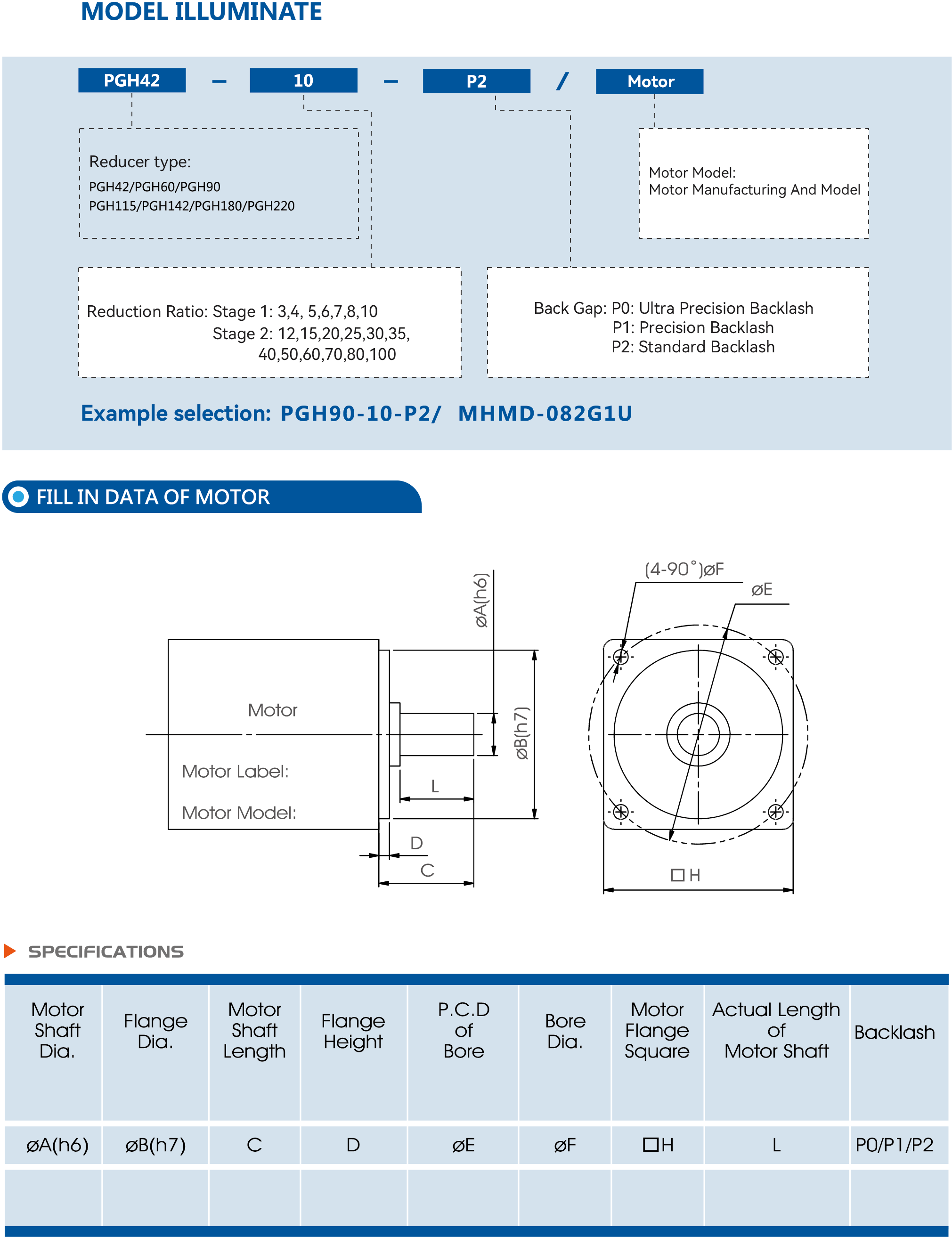

Ordering Instructions / Customer Fill Out