95 Directly connected to the front fisheye ear shaft

Product features: Closed-loop servo control, control accuracy reaches 0.01mm; precision control thrust, increase pressure sensor, control accuracy can reach 1%; it is easy to connect with PLC and other control systems to achieve high-precision motion control. Low noise, energy saving, clean, high rigidity, impact resistance, ultra-long life, simple operation and maintenance. The electric cylinder can work without failure in harsh environments, and the protection level can reach IP66. Long-term work, and achieve high strength, high speed, high-precision positioning, smooth movement, low noise.

Therefore, it can be widely used in the papermaking industry, chemical industry, automotive industry, electronics industry, mechanical automation industry, welding industry, etc.

Product introduction: It can provide very flexible installation configuration, a full range of installation components: installation front flange, rear flange, side flange, tail hinge, ear shaft installation, guide module, etc.; it can be installed in line with the servo motor, or installed in parallel; various accessories can be added: limit switch, planetary reducer, pre-tightening nut, etc.; the drive can choose AC brake motor, DC motor, stepper motor, servo motor

Parameter Table

| Cylinder Type | Thrust(KG) | Stroke(mm) | Speed(mm/s) | Screw Diameter(mm) | Push Rod Diameter(mm) | Output Thread Head |

| MODEL | LOAD | STROKE LENGTH | SPEED | SCREW DIAMETER | PUSH ROD DIAMETER | OUTPUT THREAD HEAD |

| 45# | 60 | ≤200 | 200 | 12 | 22 | M12*1.25 |

| 65# | 350 | ≤1000 | 200 | 16 | 30 | M16*1.5 |

| 75# | 800 | ≤1000 | 200 | 20 | 35 | M20*1.5 |

| 95# | 1500 | ≤1500 | 200 | 25 | 45 | M24*1.5 |

| 110# | 3000 | ≤1500 | 200 | 32 | 50 | M30*2.0 |

| 135# | 5000 | ≤2000 | 200 | 50 | 100 | M52*2.0 |

| 160# | 10000 | ≤2000 | 200 | 63 | 100 | M52*2.0 |

| 190# | 20000 | ≤2500 | 200 | 80 | 110 | M56*2.0 |

| 250# | 30000 | ≤3000 | 200 | 100 | 145 | M80*2.0 |

| (mm) Effective Stroke | Standard Stroke | (mm) Itinerary suggestilon | |||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | ≤1500 | |

| (kg) Weight | 16.00 | 17.50 | 19.00 | 20.50 | 22.00 | 23.50 | 25.00 | 26.50 | 28.00 | 29.50 | … |

| Remarks: The weight of 0,35kg will be increased for every 100 mm increase in travel | |||||||||||

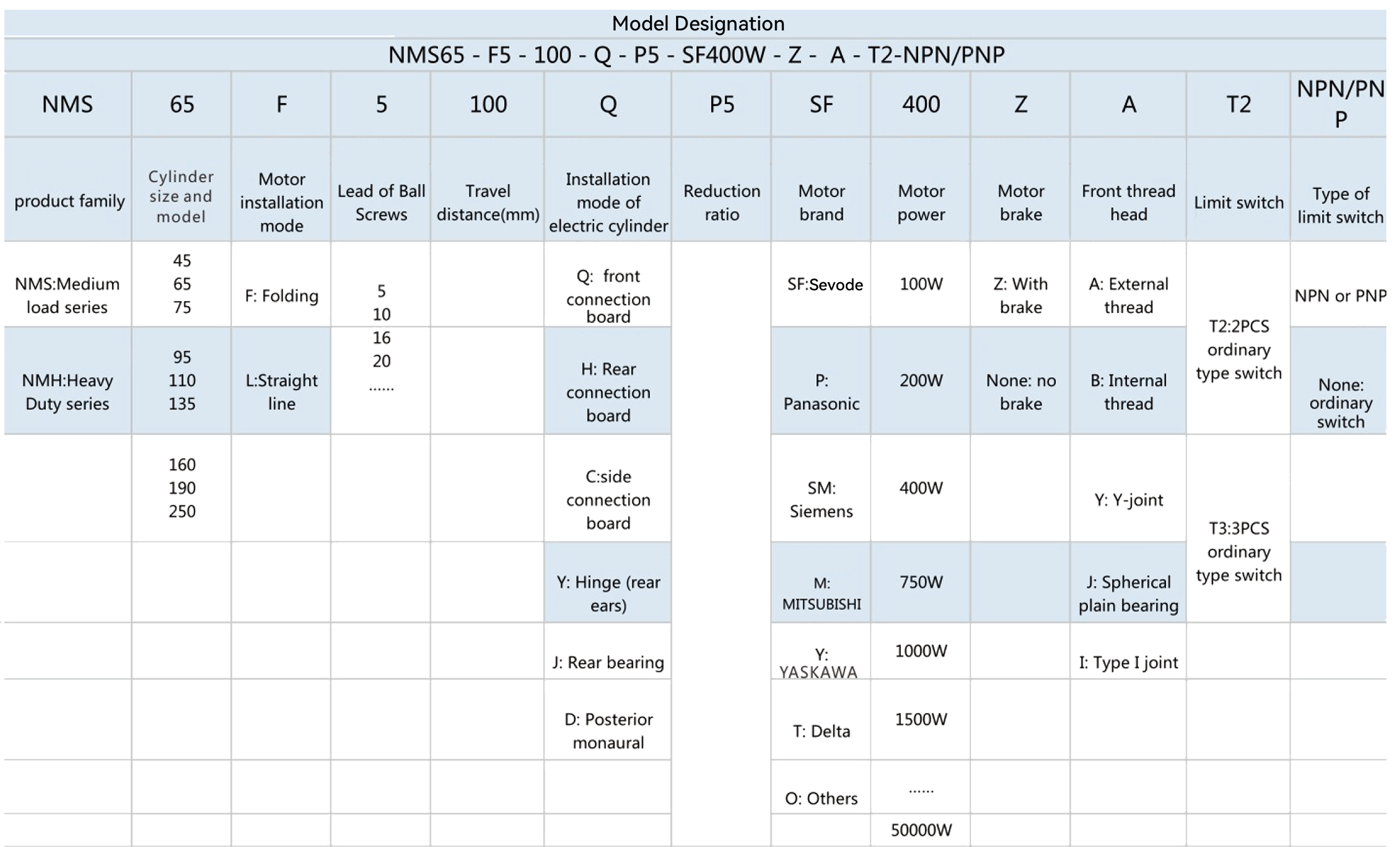

Ordering Instructions / Customer Fill Out